Equipment

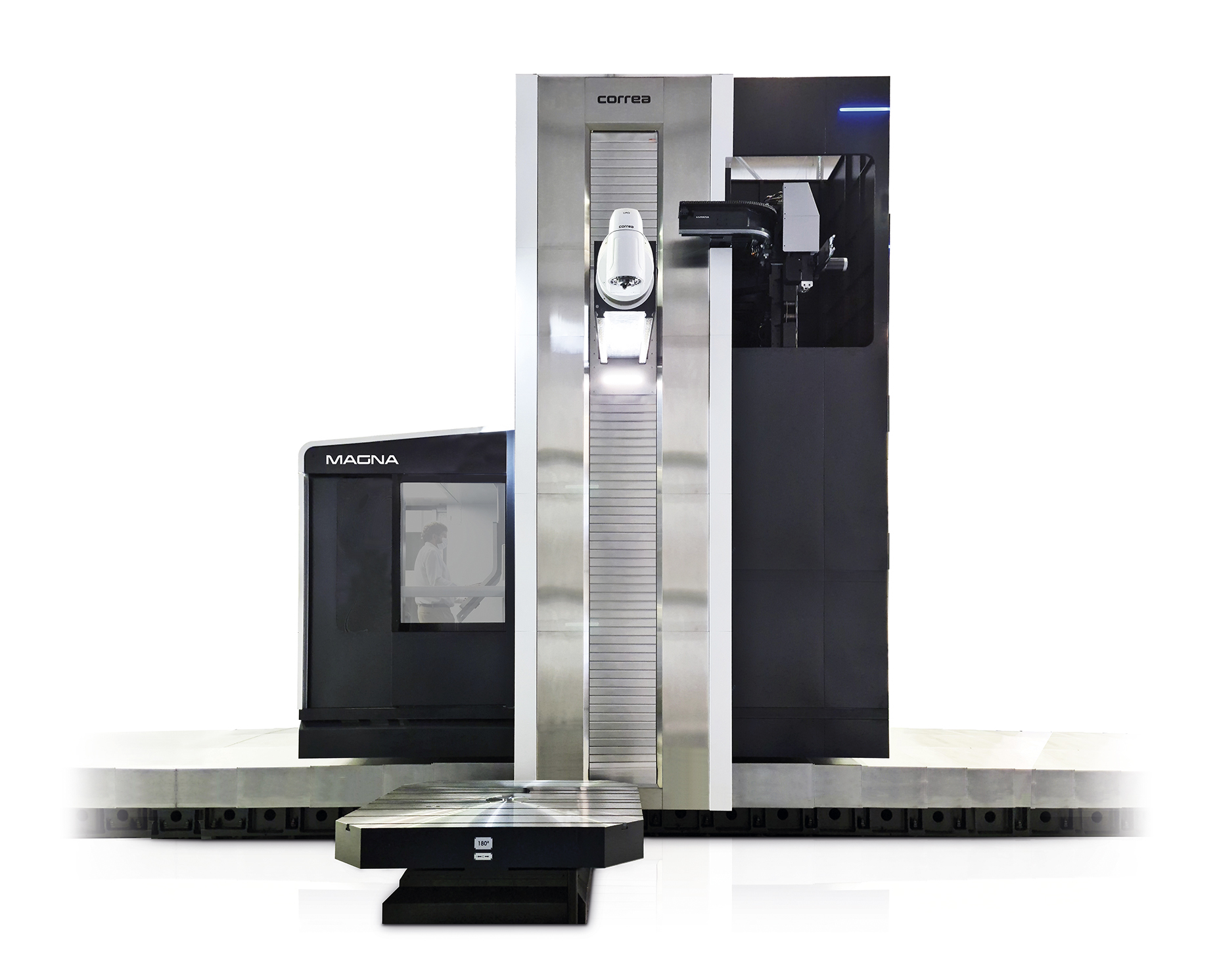

1. Milling machining center MAGNA-105

The MAGNA represents the pure box-in-box concept, also incorporating two mechanical systems dynamically compensating for both ram droop and frame tipping. The result: tremendous chip removal capacity, maintaining very high levels of precision throughout the machine’s volume

Х – 10500 мм, Y – 4000 мм, Z – 2000 мм.

Rotary table 2500x2500 mm, linear axis 1500 mm, 40,000 kg., Heidenhain optical rulers Endat model (0.010 µm).

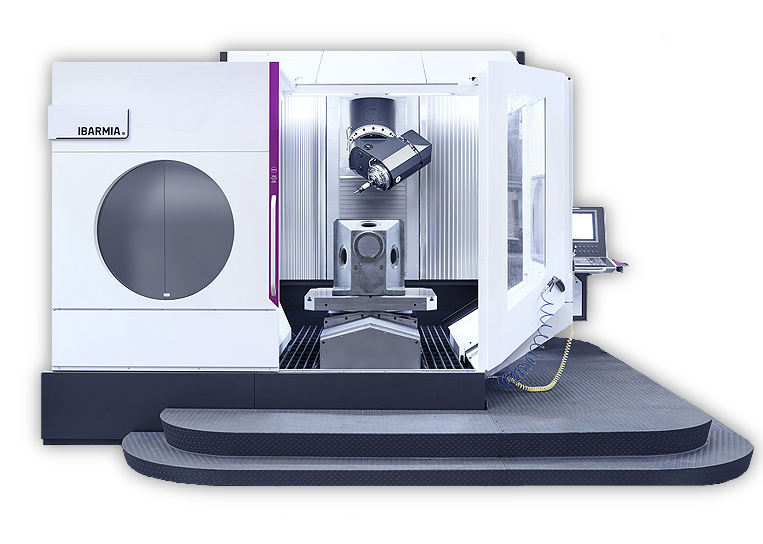

2. Milling processing center of the model VERXA M-125

The VERXA represents the concept of a high-performance bridge-type machine with mobile table. Its structural design and thermal symmetry permit machining of large parts while maintaining high dynamics and geometric precision.

X is 12,500 mm, Y is 4250 mm, the distance between the columns is 3750 mm, Z is 2500 mm. Heidenhain optical rulers Endat model (0.010 µm).

3. Milling machine Norma MG 25

Bed type milling machine NORMA MG with lateral ram offers robustness thanks to its ram guiding system in L. This machine has different options of rotary and turning table which provides great flexibility to perform several machining operations. The milling machine has 4+2 axes to offer high flexibility maintaining robustness and precision of Correa indexed milling heads with rotation every 0.02º, patented by Nicolás Correa.

X – 2500 mm, Y – 1250 mm, Z – 1500 mm

The working surface is 1600x1600, the maximum load on the table is 8000 kg.

4. Milling and turning machine Norma MG 35

Bed type milling machine NORMA MG with lateral ram offers robustness thanks to its ram guiding system in L. This machine has different options of rotary and turning table which provides great flexibility to perform several machining operations. The milling machine has 4+2 axes to offer high flexibility maintaining robustness and precision of Correa indexed milling heads with rotation every 0.02º, patented by Nicolás Correa.

X – 3500 mm, Y – 1500 mm, Z – 2000 mm

The working surface is 1600x1600 mm. The maximum load on the table is 8000 kg.

5. Milling processing center of the model FENIX-90

The FENIX represents a new concept of travelling column machine with lateral ram. Highly robust based on a system of L-guided ram. High precision thanks to the mechanical system of ram droop correction. A flexible machine appropriate for roughing and finishing operations.

X – 9000 mm, Y – 2000 mm, Z – 1500 mm.

The working surface is 2000x1600 mm. The maximum load on the table is 10000 kg.

6. 5-axis universal machining center THC12 Extreme

Universal machining center for 5-axis machining of large diameter parts, focused on high productivity through the integration of multitasking technology and automation systems

X – 1200 mm, Y – 1300 mm, Z – 1000 mm, The range of inclination of the CNC head is 15 °/+195 °, C - 360 °. The table is 800x800 mm. The maximum load on the table is 2000 kg.

7. 5-axis universal machining center THR16 Multiprocess

Universal machining center for 5-axis machining of large diameter parts, focused on high productivity through the integration of multitasking technology and automation systems

X – 1600 mm, Y – 1600 mm, Z – 1200 mm, The range of inclination of the CNC head is 45 °/+135 °, C - 360 °. The table is 1200 mm. The maximum load on the table is f6000/3000 kg.

8. Horizontal Milling machining center FT8000 с ЧПУ Siemens 840D sl.

Solid machine construction, sound process experience, a wealth of milling expertise – these are the basic ingredients for our F series 5-axis machining centres. The benefits to you are obvious: 5-axis machining with maximum output and top quality, even during continuous operation. The HELLER F-series 5-axis machining centre is the right choice for anyone wanting to perform numerous functions on one machine and produce reliably, not just today but in the future too.

X – 1250 mm, Y – 1200 mm, Z – 1400 mm. The maximum load on the table is 2000 kg.

9. Horizontal Milling machining center CT8000 с ЧПУ Siemens 840D sl.

Powerful milling is a matter of course for HELLER machining centres. If the turning machining strategy is added, conventional milling dimensions are soon forgotten. The net result from turning, milling and HELLER's expertise in machine construction is our C-series 5-axis milling/turning machining centre – unique in terms of output, reliability and resilience.

X – 1250 mm, Y – 1250 mm, Z – 1400 mm. The maximum load on the table is 2000 kg.

10. Horizontal Milling machining center H6000 с ЧПУ Siemens 840D

The perfect 4-axis machining centre must be capable of being configured to your requirements, produce reliably even under extreme loads and offer a fair price/performance ratio. Our solution: HELLER H-series 4-axis machining centres.

X is 1000 mm, Y is 1000 mm, Z is 1000 mm. The maximum load on the table is 1400 kg.